Uncategorized

The Ultimate Guide to Small Diameter Blades: Applications and Benefits

In the world of cutting innovation, accuracy and flexibility are key. Whether you’re a proficient contractor or a DIY devotee, having the right apparatuses is fundamental for accomplishing high-quality comes about.

One such device that regularly goes beneath the radar but plays a pivotal part in numerous applications is the little breadth edge. These edges, with their compact measure and precision-engineered plan, offer interesting benefits that make them crucial in certain tasks.

This comprehensive direct will investigate the different applications and benefits of small-diameter blades, giving you with the information you require to select the right edge for your particular needs. We’ll too touch on related apparatuses like peacock saws and bass blaster, which can improve the execution of small-diameter edges. Whether you’re cutting tile, stone, or other materials, this direct will help you get why little breadth edges are a must-have in your cutting toolkit.

Understanding Small-Diameter Blades

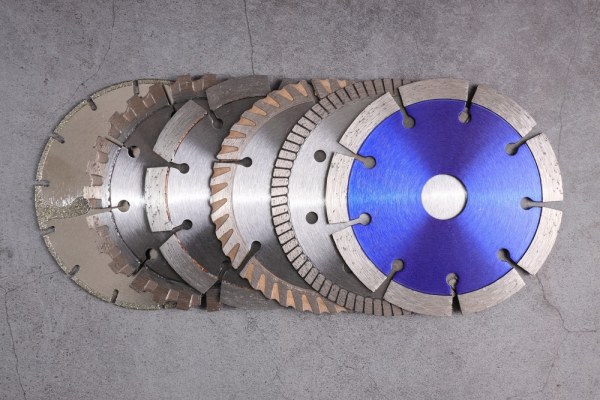

Small-diameter edges are regularly characterized as edges with a breadth of less than 6 inches. These edges are outlined for accuracy in cutting in tight spaces or on sensitive materials where bigger edges might be as well clumsy or forceful. The compact measure of small diameter blades permits greater control and exactness, making them perfect for nitty-gritty work.

Despite their measure, small-diameter blades pack an effective punch. They are regularly made from high-quality materials such as jewel or carbide, which gives them the strength and sharpness required to cut through intense materials with ease. The little measure permits these edges to be utilized in handheld devices, making them unimaginably flexible and helpful for a wide run of applications.

Key Applications of Small-Diameter Blades

- Tile Cutting

One of the most common applications for small-diameter blades is in tile cutting. When working with tiles, accuracy is pivotal to guarantee clean cuts and a proficient wrap-up. Huge edges can be troublesome to move, particularly when making complex cuts around corners or edges. This is where little-diameter edges come into play.

Tile blades that are little in breadth offer the control required to make exact cuts without harming the tile. Whether you’re cutting ceramic, porcelain, or common stone tiles, a little breadth edge guarantees smooth edges and diminishes the hazard of chipping or breaking. These edges are especially valuable when working on custom tile establishments, where precision is paramount.

- Metal Cutting

Another zone where little breadth edges excel is in metal cutting. Whether you’re cutting through lean metal sheets, channels, or other metal components, a little breadth edge permits greater control and exactness. This is particularly vital in applications where the cut needs to be clean and exact, such as in car or mechanical work.

- Masonry and Stonework

Masonry and stonework require instruments that can handle intense materials while still conveying exact results. Little-diameter edges are frequently utilized in these applications for cutting stone, brick, or concrete. The smaller measure permits for more prominent control, which is basic when making nitty-gritty cuts or working in tight spaces.

- Woodworking

While little diameter edges are frequently related to harder materials like tile and metal, they are moreover profoundly successful in carpentry. These edges are idealized for making exact cuts in wood, particularly when working on nitty-gritty or complicated plans. The smaller measure permits for more prominent control, making it simpler to accomplish clean, exact cuts.

Small-diameter blades are especially valuable when working on ventures that require a tall level of detail, such as cabinetry, furniture making, or enhancing woodwork. The accuracy advertised by these edges guarantees that your cuts are clean and your wrapped-up item looks professional.

Enhancing Performance with Related Tools

While little diameter edges are effective instruments on their claim, their execution can be improved when utilized in conjunction with other specialized devices. Here are a few related apparatuses that can complement your little breadth blade:

Peacock Saws

Peacock saws are known for their flexibility and accuracy. These saws are regularly prepared with little breadth edges, making them perfect for nitty-gritty work in tight spaces. Whether you’re cutting wood, metal, or tile, a Peacock saw with a small diameter edge offers the control and precision required to accomplish proficient results.

Bass Blaster

The Bass Blaster is a cutting-edge device outlined for high-performance cutting errands. When combined with a small diameter edge, the Bass Blaster conveys uncommon accuracy and control, making it easier to handle indeed the most challenging cuts. Whether you’re cutting through metal, tile, or stone, the combination of the Bass Blaster and a little breadth edge guarantees clean, precise cuts each time

Turbo Chaser

For contractors who are required to handle intense cutting assignments, the Turbo Chaser is a go-to instrument. This high-performance edge is planned for speed and effectiveness, permitting for fast, clean cuts through the hardest materials. When combined with a little diameter edge, the Turbo Chaser upgrades the tool’s capabilities, making it simpler to total indeed the most challenging jobs.

Diamond Cutting Blade

When working with difficult materials like stone, brick, or concrete, a jewel cutting edge is fundamental. These edges are outlined to cut through intense materials with ease, giving clean, exact cuts without causing over-the-top wear on the edge of the device. A little breadth jewel cutting edge is especially valuable for detailed masonry work or when working in tight spaces.

Benefits of Small-Diameter Blades

- Precision and Control

One of the essential benefits of little breadth edges is the accuracy and control they offer. The smaller measure permits for more prominent maneuverability, making it simpler to make nittygritty cuts with a tall degree of precision. This is especially vital in applications where exactness is key, such as tile cutting, metalwork, or nitty-gritty woodworking.

- Versatility

Small-diameter edges are fantastically flexible and can be utilized in a wide extend of applications. From cutting tile and metal to working with wood and stonework, these edges are an important expansion to any toolkit. Their flexibility makes them reasonable for both proficient contractors and DIY devotees alike.

- Durability

Despite their small estimate, little diameter edges are built to final. Made from high-quality materials like jewel or carbide, these edges are planned to withstand the rigors of heavy utilization without losing their sharpness or viability. This solidness guarantees that your venture in a little breadth edge will pay off in the long run.

- Ease of Use

Small diameter edges are outlined for ease of utilization, making them an incredible choice for both experts and tenderfoots. The smaller estimate makes them simpler to handle, decreasing weariness and making it easier to accomplish the craved comes about. Whether you’re working on a huge venture or a little repair work, little breadth edges make the errand more manageable.

Conclusion

Small diameter edges are an imperative apparatus for anyone in cutting assignments, whether in development, stonework, metalwork, or carpentry. Their exactness, flexibility, and strength make them irreplaceable in a wide run of applications. From cutting tile and metal to working with wood and stone, little breadth edges offer the control and precision required to accomplish proficient results.

By understanding the different applications and benefits of little-diameter edges, you can make educated choices approximately which edge to utilize for your particular needs. Whether you’re a proficient contractor or a DIY devotee, contributing to a high-quality little breadth edge will improve your cutting capabilities and enhance the quality of your work.