Uncategorized

Top Gorilla Blades for Heavy-Duty Cutting Applications

When it comes to heavy-duty cutting applications, having the right apparatuses is significant. Exactness, strength, and productivity are vital, and that’s where Gorilla Edges come into play. Outlined for the hardest errands, Gorilla Blades stand out as a driving choice for experts in the development and masonry industries.

In this comprehensive direct, we’ll investigate the best Gorilla Blades for heavy-duty cutting applications, highlighting their unique highlights and benefits. We’ll also delve into related items and advancements from Empire Cutting, giving you the data required to make an educated choice.

The Evolution of Cutting Technology

Cutting innovation has come a long way, driven by the requirement for superior execution and longer-lasting devices. Present-day headways have driven the creation of cutting edges that not as were met but surpass the requests of heavy-duty applications. Among these advancements, Gorilla Edges have risen as a game-changer, advertising unparalleled cutting control and resilience.

Why Choose Gorilla Blades?

Gorilla Blades are designed with a center on quality, accuracy, and life span. These edges are outlined to handle an assortment of materials, counting concrete, brickwork, and stone, making them flexible devices for any proficient. Their vigorous development guarantees they can withstand the rigors of requesting cutting assignments, giving steady execution and expanded edge life.

Top Gorilla Edges for Heavy-Duty Applications

- Gorilla Diamond Blades

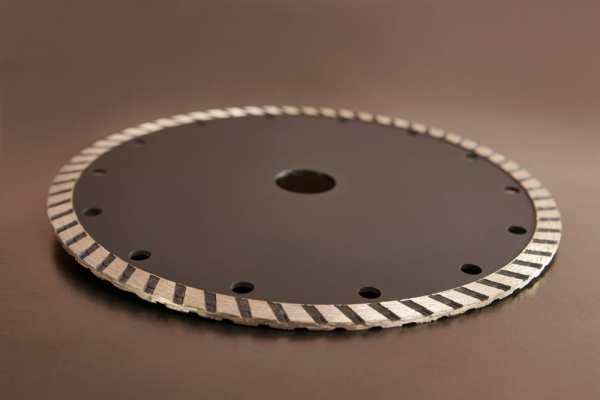

One of the standout items in the Gorilla Blades lineup is the Gorilla Diamond Blades. These edges are implanted with high-quality jewels, improving their cutting productivity and solidness. The jewel sections are fastidiously created to give clean, exact cuts, decreasing the requirement for extra wrapping-up work.

Key Features:

- High Diamond Concentration: The Gorilla Diamond Blades boast a tall concentration of diamonds, ensuring superior cutting execution and longevity.

- Advanced Holding Innovation: The edges utilize progressed holding methods to secure the diamond segments, improving the blade’s solidness and cutting speed.

- Versatility: Reasonable for a wide run of materials, counting concrete, brick, and stone, making them perfect for different heavy-duty applications.

- Gorilla Blades with Small Diameter

For errands requiring better exactness and maneuverability, small-diameter blades from the Gorilla Edges Extension are a fabulous choice. These edges culminate in perplexing cutting assignments where bigger edges might not be suitable.

Key Features:

- Enhanced Accuracy: The smaller diameter permits more exact cuts, making them perfect for detailed work.

- Ease of Utilize: Lightweight and simple to handle, these edges culminate for assignments that require a tall degree of control.

- Compatibility: These edges can be utilized with different cutting devices, including their flexibility and practicality.

- Gorilla Diamond Blade for Grinder

When it comes to crushing applications, the diamond blade for grinder from Gorilla Edges offers unmatched execution. These edges are outlined to handle high-speed pounding errands with ease, giving smooth and effective results.

Key Features:

- High-Speed Cutting: The jewel sections are designed for high-speed applications, guaranteeing quick and productive grinding.

- Durability: Built to withstand the tall requests of crushing errands, these edges offer amplified life span and steady performance.

- Precision Pounding: The edges give smooth and exact crushing, decreasing fabric wastage and upgrading in general efficiency.

- Empire Cutting: A Trusted Title in Cutting Technology

Empire Cutting is famous for its commitment to quality and advancement in cutting innovation. The company’s items are outlined to meet the highest guidelines of execution, making them a trusted choice for experts worldwide.

Innovations in Diamond Cutting Blades

Empire Cutting has ceaselessly pushed the boundaries of what’s conceivable with diamond cutting blade technology. These edges are built to provide remarkable execution, combining the quality of diamonds with progressed fabricating techniques.

The Benefits of Utilizing Diamond Blades

Diamond Edges have become the go-to choice for experts due to their various advantages. From expanded cutting speed to upgraded toughness, jewel edges offer a few benefits that make them irreplaceable in heavy-duty cutting applications.

Enhanced Cutting Speed

One of the essential advantages of diamond edges is their cutting speed. The hardness of diamonds permits quicker cutting compared to conventional edges, altogether improving proficiency and productivity.

Increased Durability

Diamond edges are known for their lifespan. The diamond segments are profoundly safe from wear and tear, guaranteeing that the edges maintain their cutting edge for longer periods. This toughness translates to fetched savings, as the edges require fewer visit replacements.

Precision and Clean Cuts

The accuracy advertised by diamond blades is unmatched. The sharpness and quality of the diamond portions permit for clean, exact cuts, decreasing the requirement for extra finishing work and improving the general quality of the project.

Choosing the Right Gorilla Blade for Your Needs

Selecting the right Gorilla Blade depends on the particular necessities of your extension. Here are a few variables to consider when making your choice:

Material to Be Cut

The sort of fabric you arrange to cut is a significant figure in selecting the suitable edge. Guarantee that the edge you select is planned to handle the particular fabric, whether concrete, brick, or stone.

Blade Breadth and Section Height

Consider the diameter and fragment tallness of the edge, as these variables impact the profundity of cut and edge life expectancy. Bigger diameters are appropriate for deeper cuts, whereas higher portions give longer edge life.

Cutting Speed and Power

Match the blade’s details with the cutting speed and control of your hardware. Higher speed and control can improve cutting proficiency but may also cause quicker wear. Guarantee compatibility for ideal performance.

Wet vs. Dry Cutting

Determine whether you require an edge for damp or dry cutting. Damp cutting includes utilizing water to cool the edge and decrease cleaning, making it appropriate for persistent, heavy-duty errands. Dry cutting is helpful for fast, on-the-spot cuts where water isn’t promptly available.

Conclusion

Gorilla Edges has set a modern standard in heavy-duty cutting applications, advertising uncommon execution, solidness, and accuracy. Whether you’re working on development, stonework, or any other requesting errand, Gorilla Edges give the reliability and proficiency required to get the work done right.

Empire Cutting’s commitment to advancement and quality is apparent in its run of cutting devices, counting the diamond blade for processor, little breadth edges, and other high-performance items. These instruments are planned to meet the assorted needs of experts, guaranteeing prevalent results in every project.